Design in the Fast Lane

We developed a master plan for the new facility that closely modeled Bridgestone’s sister manufacturing plants in Japan, and featured a similar footprint that would allow improvements to be replicated across other facilities. The plant would also incorporate work-flow processes and technologies developed at the Japanese counterparts. Working on a fast-track schedule, site evaluation and planning for the project began in August; site clearing and mass-grading commenced in October; design of the plant started in November; and construction of the plant officially began in December.

A Showcase Facility

We worked closely with Bridgestone’s plant manager and engineering staff to design an inspiring 65,000-square-foot main office for its employees, customers and visitors. Oftentimes, tire plants are designed around the production equipment required for the manufacturing of tires, and the office areas are just an afterthought. Bridgestone tasked us with delivering a “wow” factor in the design of the main office space. To do that, we incorporated sustainable materials and advanced technology systems from Firestone Building Products—one of their subsidiaries.

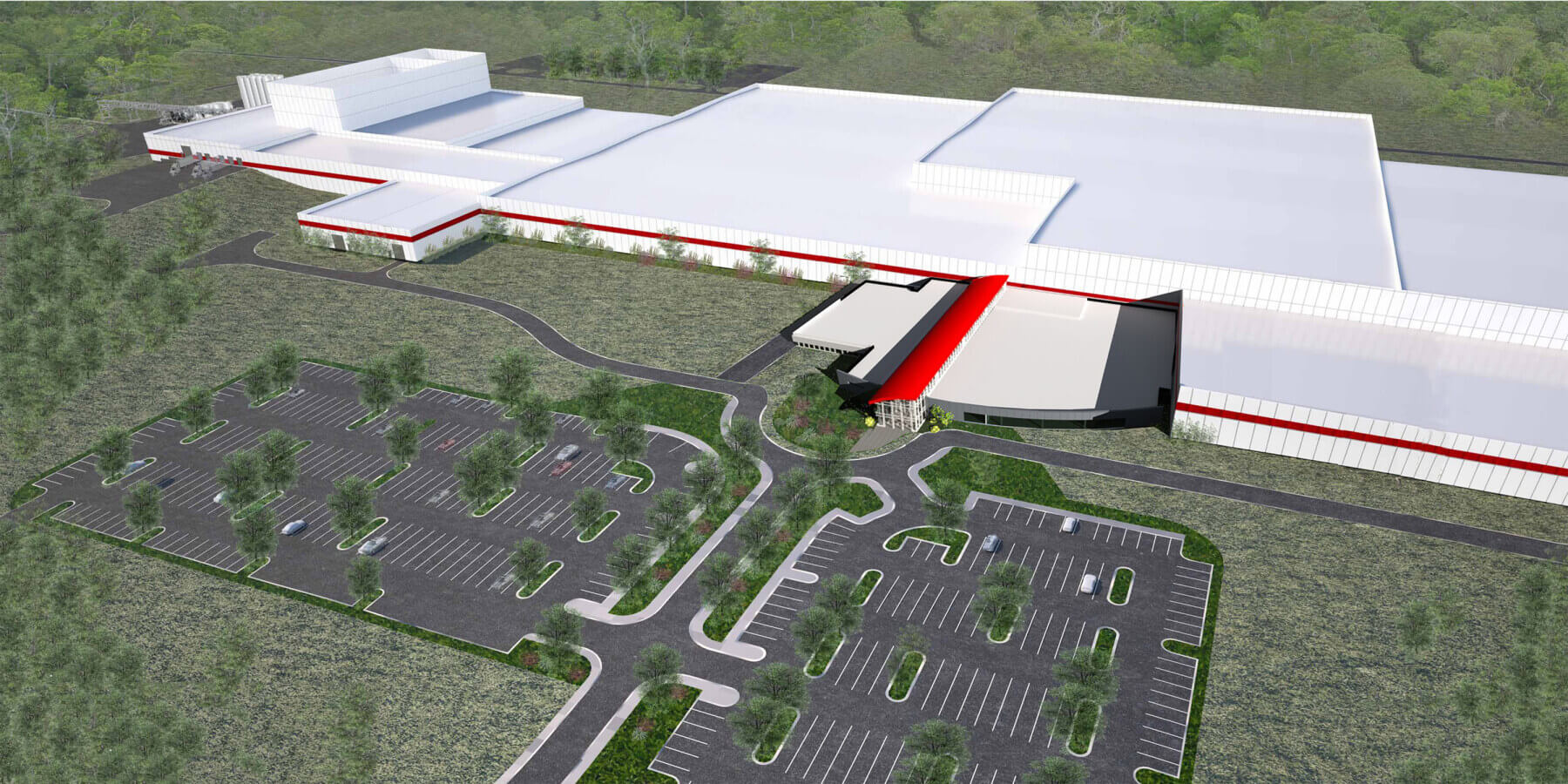

Our design incorporates Firestone’s UltraPly™ TPO roofing system, along with curved, standing-seam metal roof panels, insulated metal wall panels, roof pavers made from recycled rubber, and a geomembrane for retention ponds and water harvesting areas around the site. The main guardhouse at the entrance to the facility also incorporates Firestone Building Products, giving visitors an eye-catching first impression of what lies beyond.

From the guardhouse, a winding drive runs approximately three-quarters of a mile to the main office, through which all plant and corporate staff enter the facility. This single point of entry facilitates a sense of camaraderie, and reinforces the company’s “one team” philosophy. Once inside the office’s main corridor, employees can make their way to the various departments inside the office, or on the production floor.

The main office includes the company’s engineering and accounting departments, human resources and upper-management offices, as well as a cafeteria, a fitness center for employees, a company store and a large “all-plant” conference room.

The interior design also integrates products from Firestone, including metal ceiling panels, exterior soffits, and metal column wraps in Bridgestone’s vibrant black, white and red color scheme.

One Team, One Planet

The Aiken County plant, its roadways and parking lots take up approximately 150 acres of the 550-acre greenfield site. Our master plan situated the plant with adequate room to double the facility to the north while preserving the natural habitat and wetland areas.

As part of Bridgestone’s commitment to protecting and preserving the natural environment, we designed the tire plant to meet LEED Silver certification standards. Additionally, we ensured no stormwater was discharged from the site. Instead, it’s used or restored to the water table. We also developed a large-scale rainwater harvesting system to augment water sources for certain uses like process water and restrooms, which will save substantial amount of water. Other sustainable design strategies include high-efficiency lighting, controls and water fixtures, and the recycling of 99 percent of all production waste.

Our design provides the client with a stunning showcase facility that not only supports Bridgestone’s manufacturing needs both globally and locally, but reflects its steadfast commitment to remaining an environmentally conscientious company. The project represents one of the largest full-service efforts ever undertaken by our Industrial group. Since the completion of the plant, we have been awarded two additional greenfield tire plants, and we continue to provide ongoing design support to Bridgestone.