Life in the Fast-Track Lane

Gresham Smith provided full architectural and engineering services for the project on a fast-track schedule of just 14 months for design and construction—an unprecedented time frame given the complexity and magnitude of the project scope. Close teamwork was the foundation of the project’s success, with daily coordination between the engineering and design team as well as other project team members proving essential. The project was also aided by the latest BIM technology, which allowed an on-site manager to update models in real-time to address construction challenges.

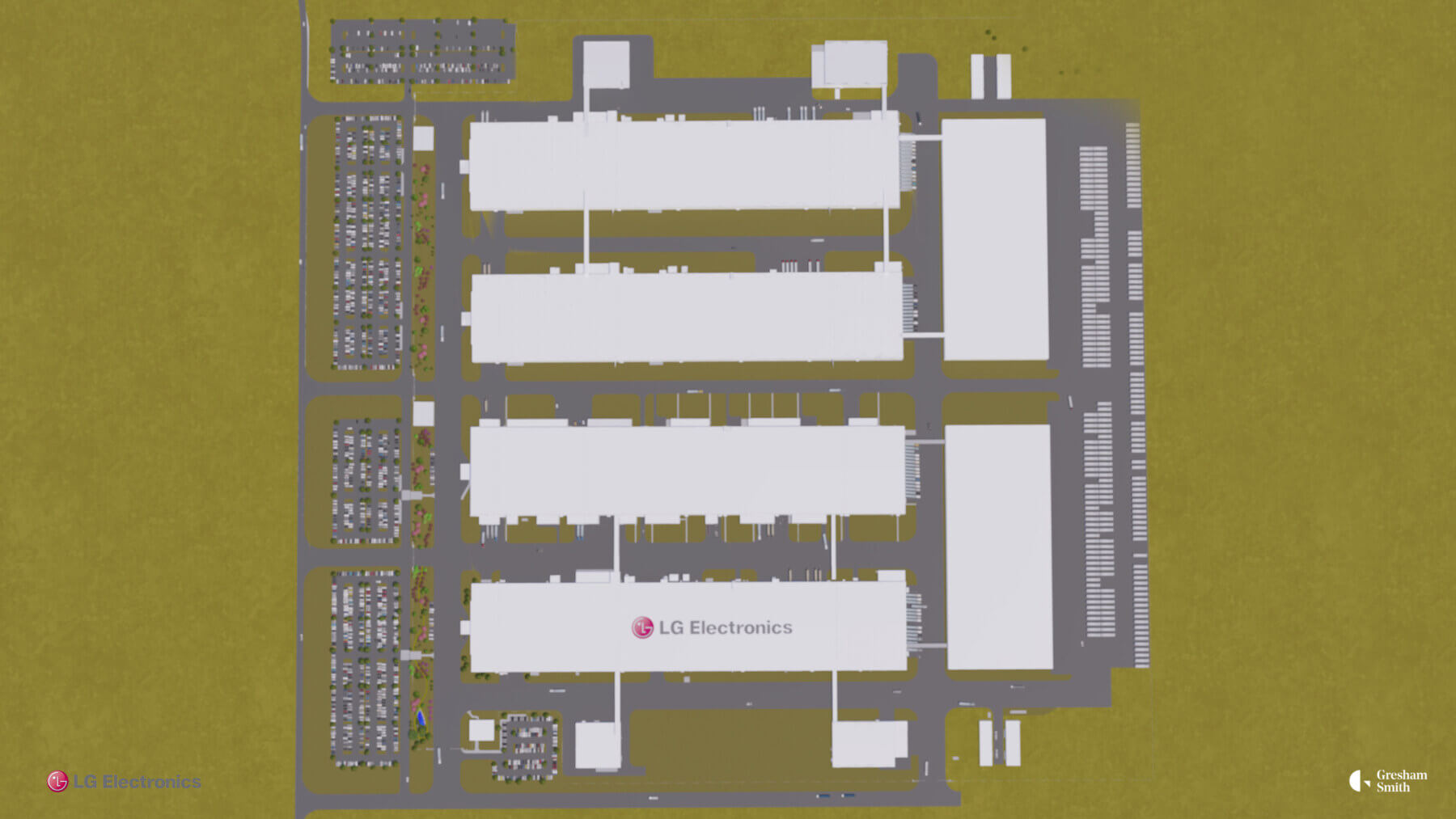

The Big Box Theory

Our client didn’t want to simply drop a “big-box” plant into the middle of their 310-acre site. Supporting LG’s wishes, our design creates a signature front facade for the new facility, featuring the distinctive “W” shape of the main building’s exterior columns—a subtle nod to the washing machines that are manufactured within.

Bringing VE to LG

Gresham Smith provided value engineering for all building systems. The plant comprises two main assembly lines—one for top-load washers and one for front-loaders—as well as a central utility building and additional support buildings, including a warehouse for materials and appliances. The design also features a utility support area, a shipping and receiving area, hazardous materials storage, a recycling center and a guest information center.

A True Community Asset

Honoring LG’s commitment to being a true asset within the Clarksville community, the new “smart” manufacturing facility embodies both an engineering feat and a foreign, direct-investment success story, evidencing the growth of the U.S. Industrial sector. To date, the plant employs almost 700 employees who work synergistically with the facility’s leading-edge automated processes.

A Blueprint for the Future

While there are no concrete plans yet for expansion, we delivered a master plan for the site as well as design concepts if LGE decides to add production capacity in the future.