A Non-Traditional Approach

To minimize the social and economic impacts to Nashville’s central business and entertainment districts, TDOT elected to use Accelerated Bridge Construction (ABC) versus a more traditional bridge replacement method. By employing ABC, it was estimated the project could be completed within a total of 13 weekend full-closure periods instead of up to three years of reduced traffic lanes.

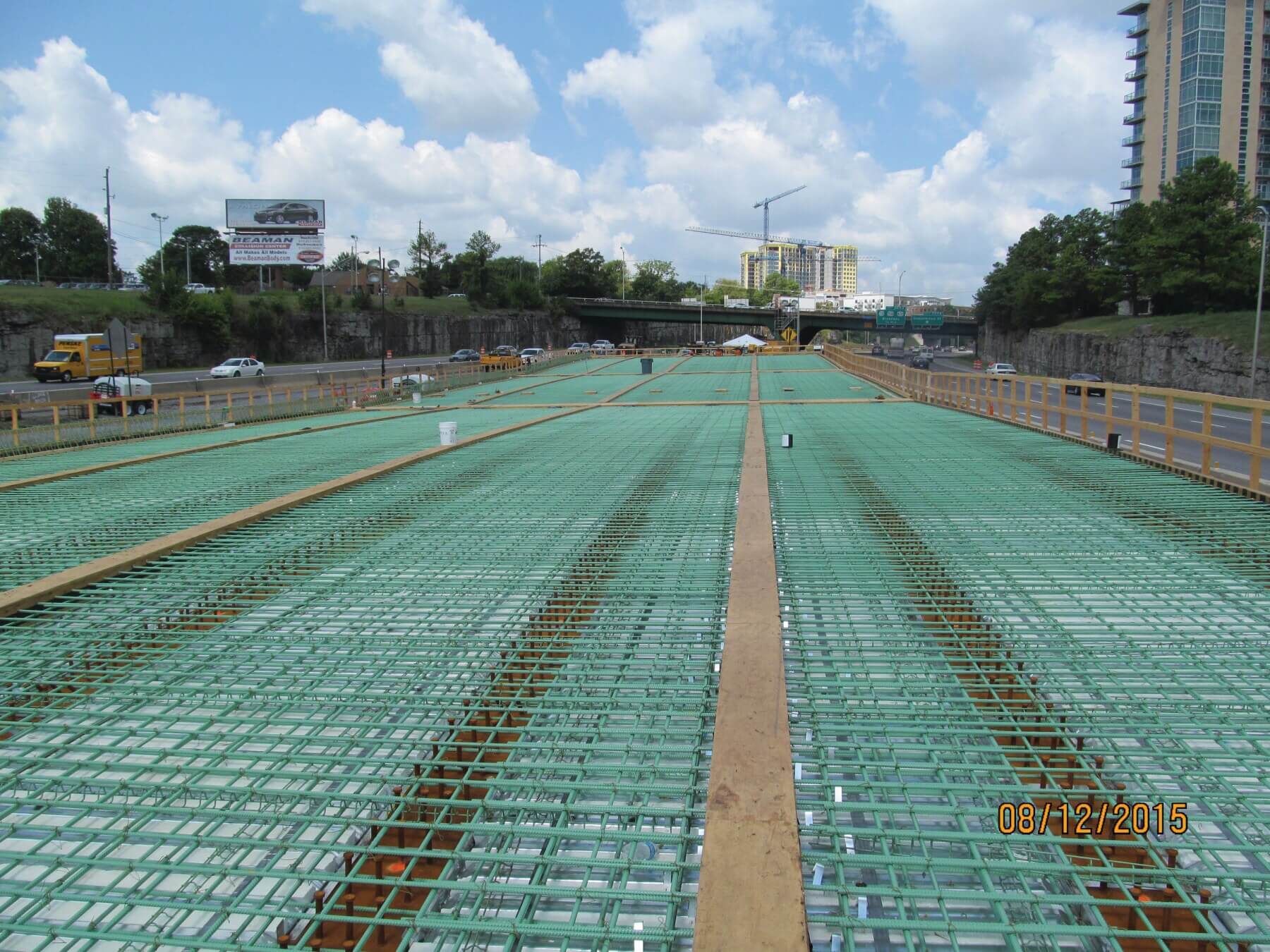

The Fix Is In

After identifying potential options for restoring each of the four sets of bridges, Gresham Smith determined that each crossing site required a different rehabilitation solution. To meet the aggressive schedule, numerous innovative engineering techniques were employed. Structural steel superstructure units were used on four of the eight bridges. These units were fabricated off-site at a “Bridge Farm” in the median of I-40, and then transported and installed during the weekend closure.

Fast-Tracking Construction

Precast concrete bridge elements were used on six of the eight bridges as a means of accelerating the overall bridge construction timeline. These components were also fabricated off-site and then shipped to the location just prior to weekend installation.

Keep the Environment in the Mix

We incorporated numerous environmentally conscious elements into the effort, including the reuse of steel beams and rebar from the existing bridges. Most notably, our team developed a special concrete mix that could be batched in trucks, saving more than 36,000 concrete bags from the waste stream. The mix, which reaches 4,000 PSI in only four hours, can be used in future TDOT projects.

ABCya!

Completed seven months ahead of schedule and utilizing only 10 weekend road closures as opposed to the allotted 13, the Fast Fix 8 Accelerated Bridge Construction project restored the four sets of mainline I-40 bridges in downtown Nashville with minimal impact to the environment, local businesses, residents and the traveling public.